Tank Seals

PRIMARY TANK SEALS

Our seals offer an optimal solution for reduction of emission from the area between an external floating roof and the tank shell. Every tank is different and operating conditions vary significantly. Local requirements on emission reduction also play a major role in the selection of the optimal seal configuration.

Tank seals play a key role in prevention of rim fires and can therefore be regarded as safety critical equipment.

Within this challenging playing field of legislation, technical and safety requirements our staff has a proven track record in supplying the optimal sealing solution. The range of seals we provide combines efficient design with optimum sealing throughout the complete rim gap.

Standards and safety

Our Secondary tank seals comply with all international standards such as API, EN, BREF IPPC, EPA, ATEX and NFPA as well as with specific requirements such as EEMUA, PGS 29 and VLAREM etc.

Engineering

During the engineering phase our team of engineers will review local emission requirements, safety aspects and tank geometry to tailor the seal to each specific tank. All other important properties, such as material selection are taken into consideration for optimal performance of the seal, this ensures a long term maintenance free service life. Seal materials have to withstand the stored product as well as the elements for longer periods of time. Our solutions will be suitable for dealing with these specific conditions.

Completely in line with the sustainability vision all emission requirements will play a major role in the decisions we make during design.

Complete Solution

We offer a complete package from engineering to commissioning. We will provide an installed seal, experienced supervision or supply drawings, installation manual and installation advice for local crews to install the seal.

LIQUID MOUNTED PRIMARY SEAL TYPES

• Shoe plate seals

• Compression shoe seals

• Foam seals and liquid filled seals

VAPOUR MOUNTED PRIMARY SEALS

• Compression plate seals

• Foam seals and liquid filled seals

• Shoe plate seals

SECONDARY SEAL TYPES

• Compression plate seals

(different tip designs available)

• Low profile seals

• Tertiary seals

Solutions

LIQUID MOUNTED GAS TIGHT SEAL TYPE

LONG SERVICE LIFE

BEST AVAILABLE EMISSION CONTROL TECHNOLOGY PER EPA AND IPPC BREF

SUITABLE FOR ALL STORED LIQUIDS, INCLUDING 100% AROMATICS

ONLY FIRE RETARDANT SEALING MATERIALS ARE USED

AVAILABLE IN SEVERAL STAINLESS STEEL GRADES AND GALVANIZED STEEL

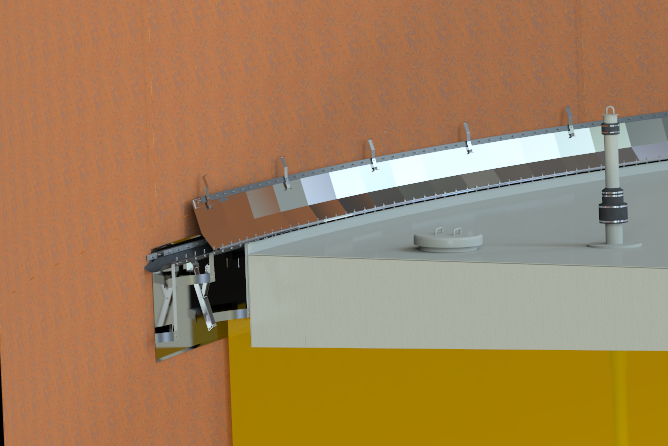

EFR PRIMARY SEALS

Over the years our mechanical shoe plate seal has proven to be one of the most resilient and versatile solutions for sealing the gap between the tank shell and floating roof. It combines excellent sealing characteristics with very good product compatibility.

IFR SEALS

Several different seal configurations are available for internal floating roofs. Each seal has its own specific areas of service. Seal materials have to be assessed and can vary depending on the product stored and other operational conditions

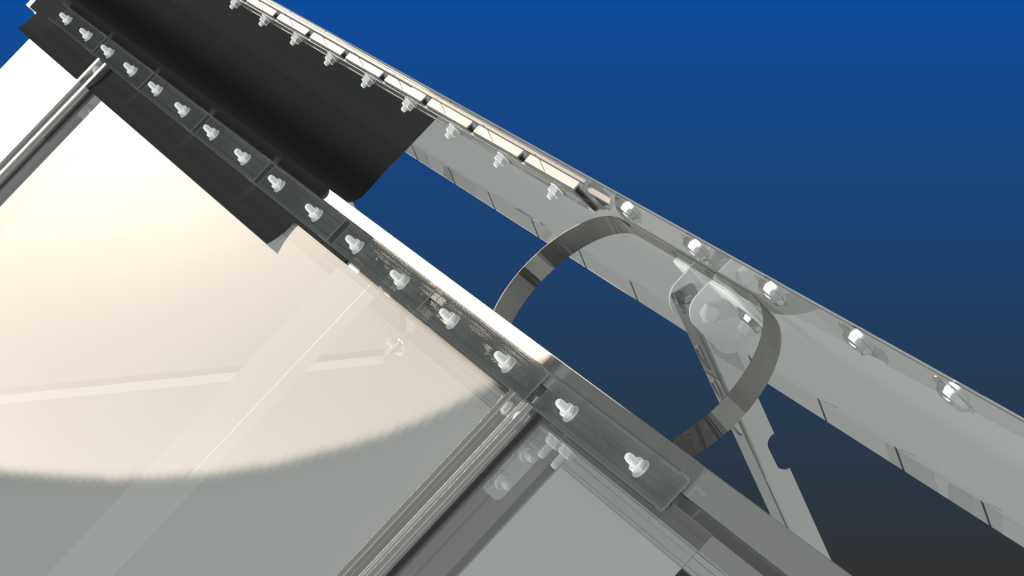

EFR SECONDARY SEALS

We offer a full range of secondary seal solutions. Secondary seals need to combine several aspects that can sometimes be contradicting. For this reason many designs have been developed that each have their own distinct advantages. A choice can be made depending on the specific priorities and combinations of safety, storage conditions, stored product properties legislation and weather conditions.