EFR Secondary Seals

Enviseal Secondary Seals

We offer a full range of secondary seal solutions. Secondary seals need to combine several aspects that can sometimes be contradicting. For this reason many designs have been developed that each have their own distinct advantages. A choice can be made depending on the specific priorities and combinations of safety, storage conditions, stored product properties legislation and weather conditions. Local requirements on emission reduction also play a major role and finally tank seals play a key role in prevention of rim fires. We will be happy to guide you to the process of selecting our best possible seal for your tank.

In the challenging playing field of legislation, technical and safety requirements our staff has a proven track record in supplying the optimal sealing solution. The range of seals we provide combines efficient design with optimum sealing throughout the complete rim gap.

All our secondary seals can be installed on all possible rim configurations. We will design the seals specifically for each tanks it is installed on and make sure it reduces emission in the best possible way. Our secondary seals are available in a wide range of materials, including galvanized steel and different grades of stainless steel.

Our secondary seals offer an optimal solution for reduction of emission from the area between an external floating roof and the tank shell. Every tank is different and operating conditions vary significantly. Local requirements on emission reduction also play a major role and finally tank seals play a key role in prevention of rim fires.

We offer a full range of secondary seal solutions. Secondary seals need to combine several aspects that can sometimes be contradicting and therefore many designs are available depending on the specific priorities and combinations of safety, storage conditions, stored product properties legislation and weather conditions. The most noteworthy aspect of a secondary seal is safety, a good secondary seal will effectively prevent rim fires regardless of weather conditions.

All our secondary seals can be installed on all possible rim configurations. We will design the seals specifically for each tanks it is installed on and make sure it reduces emission in the best possible way. All our secondary seals are available in a wide range of materials, including galvanized steel and different grades of stainless steel.

The Enviseal CI is a secondary compression plate seal with a so called intergral tip. This design is one of the most cost efficient available, while yet ensuring an adequate emission control of over 95%

If this information has triggered your interest, please click HERE to receive a quotation.

Our secondary seals offer an optimal solution for reduction of emission from the area between an external floating roof and the tank shell. Every tank is different and operating conditions vary significantly. Local requirements on emission reduction also play a major role and finally tank seals play a key role in prevention of rim fires.

We offer a full range of secondary seal solutions. Secondary seals need to combine several aspects that can sometimes be contradicting and therefore many designs are available depending on the specific priorities and combinations of safety, storage conditions, stored product properties legislation and weather conditions. The most noteworthy aspect of a secondary seal is safety, a good secondary seal will effectively prevent rim fires regardless of weather conditions.

All our secondary seals can be installed on all possible rim configurations. We will design the seals specifically for each tanks it is installed on and make sure it reduces emission in the best possible way. All our secondary seals are available in a wide range of materials, including galvanized steel and different grades of stainless steel.

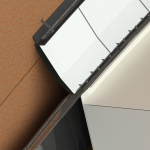

The Enviseal CL is a secondary compression plate seal with a rigid L-profile tip. This design is the most durable designs available, ensuring an adequate emission control of over 98%

- Centres the floating roof

- Prevents rain and pollution to enter the seal area and the stored product

- Excellent sealing characteristics so expenses will be saved (reduces 95-99% of emission)

- Sealing with a uniform pressure against the tank shell

- Long service life

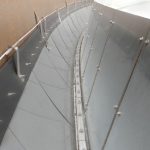

LOW PROFILE ENVISEAL LP

Our secondary seals offer an optimal solution for reduction of emission from the area between an external floating roof and the tank shell. Every tank is different and operating conditions vary significantly. Local requirements on emission reduction also play a major role and finally tank seals play a key role in prevention of rim fires.

We offer a full range of secondary seal solutions. Secondary seals need to combine several aspects that can sometimes be contradicting and therefore many designs are available depending on the specific priorities and combinations of safety, storage conditions, stored product properties legislation and weather conditions. The most noteworthy aspect of a secondary seal is safety, a good secondary seal will effectively prevent rim fires regardless of weather conditions.

All our secondary seals can be installed on all possible rim configurations. We will design the seals specifically for each tanks it is installed on and make sure it reduces emission in the best possible way. All our secondary seals are available in a wide range of materials, including galvanized steel and different grades of stainless steel.

The Low Profile ENVISEAL LP is a seal with a low building height ensuring a maximum filling capacity. The height is approximately 150-250mm above the rim of the floating roof. The springs push the tip against the tank shell and ensure functionality These springs are covered with a weather and hydrocarbon resistant antistatic fire retardant PTFE vapour fabric. This construction is key for roper runoff of rain water.

This seal is available in many different configurations depending on the service requirements and actual tank conditions.. It has been successfully used with rim gaps of over 400mm.

If this information has triggered your interest, please click HERE to receive a quotation.

- Optimises storage volume in the tank

- Prevents rain and pollution to enter the seal area and the stored product

- Excellent sealing characteristics so expenses will be saved (reduces 95-99% of emission)

- Sealing with a uniform pressure against the tank shell

- Long service life