IFR Seals

Several different seal configurations are available for internal floating roofs. Each seal has its own specific areas of service. Seal materials have to be assessed and can vary depending on the product stored and other operational conditions

Each seal we supply will be customized to fit to the tank to ensure optimal performance without gaps. We also ensure long services life and safe operation. Internal floating roof primary seals include a variety of configurations, component sizes and material options to handle any application and stored product.

- Single wiper seal (economic choice)

- Double wiper seal (economic choice)

- Liquid mounted mechanical shoe plate sea

- Foam seal

Engineering aspects:

We have developed sheets with all relevant engineering information. This includes amongst others the tank parameters, stored product, cleaning requirements, pumping speeds and pigging operation. All seal materials will fit through a 24″ manhole

If this information has triggered your interest, please click HERE to receive a quotation

Highlights

LONG SERVICE LIFE

OPTIMUM EMISSION REDUCTION

EASY TO INSTALL

TURN KEY SOLUTION AVAILABLE

IFR WIPER SEALS

Several different seal configurations are available for internal floating roofs. Each seal has its own specific areas of service. Seal materials have to be assessed and can vary depending on the product stored and other operational conditions

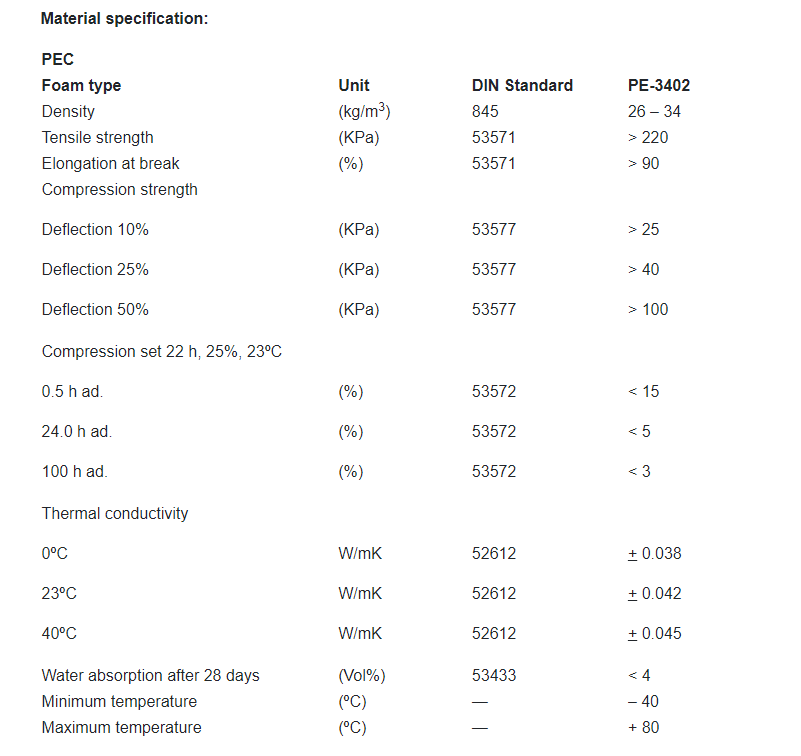

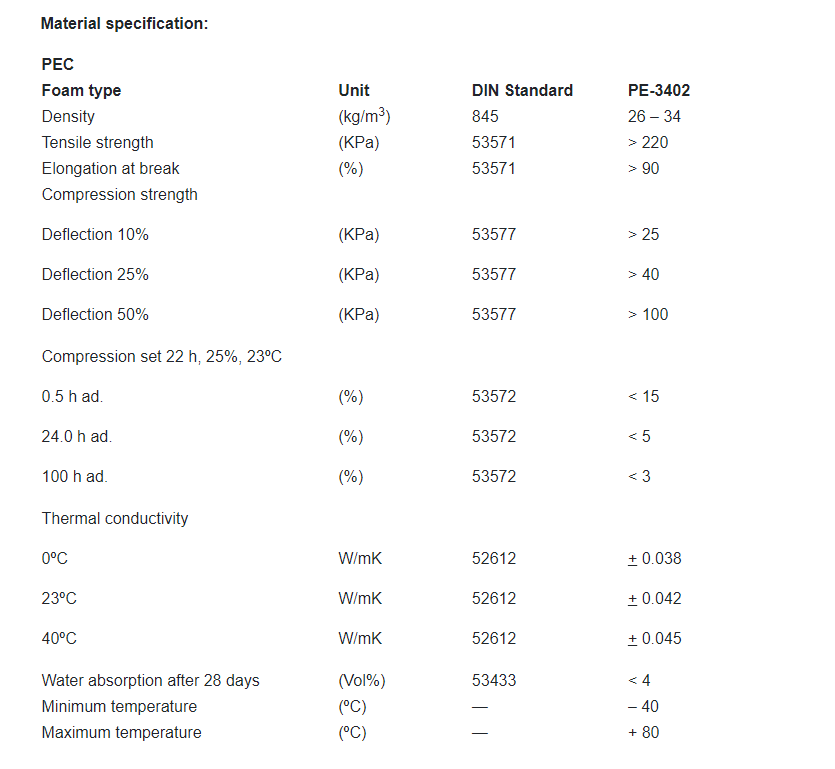

The ENVISEAL IW is an independent rim mounted wiper seal. It can be used as a primary as well as a secondary seal on an Internal Floating Roof Tank (IFRT). The wiper seal is fastened with clamp bars to the rim or riser and “wipes” up and down the tank shell along with the movements of the internal floating roof, this seals of the rim gap. The Polyethylene foam which is used for the wiper seal, has a “cross-linked” and closed cell structure. This means that de linear polymer structure has changed into a three-dimensional structure. This makes this material extremely chemical resistant.

If this information has triggered your interest, please click HERE to receive a quotation

Each seal we supply will be customized to fit to the tank to ensure optimal performance without gaps. We also ensure long services life and safe operation. Internal floating roof primary seals include a variety of configurations, component sizes and material options to handle any application and stored product.

Solutions:

- Single wiper seal (economic choice)

- Double wiper seal (economic choice)

- Liquid mounted mechanical shoe plate sea

- Foam seal

SCISSOR SHOE PLATE SEAL

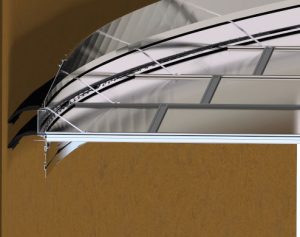

Over the years our mechanical shoe plate seal has proven to be one of the most resilient and versatile solutions for sealing the gap between the tank shell and floating roof. It combines excellent sealing characteristics with very good product compatibility. The ENVISEAL S tank seal consists of metal shoe plates that connect to the tank shell, these shoe plates are fitted with scissors and pushed against the shell with special leaf springs. A suitable vapour barrier completes the seal.

This basic design will be tailored to each specific tank. This combination of proven technology and consideration for specific tank geometry makes our ENVISEAL sealing system the best available technology for emission reduction on external floating roof tanks.

If this information has triggered your interest, please click HERE to receive a quotation

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Hang in place system

- Best available emission control technology per epa and ippc bref

- Only hand tools required for installation

- Custom designed and manufactured for each specific ifr and product service

IFR WIPER SEALS

Several different seal configurations are available for internal floating roofs. Each seal has its own specific areas of service. Seal materials have to be assessed and can vary depending on the product stored and other operational conditions

The ENVISEAL IDW is an independent double rim mounted wiper seal to be used on an Internal Floating Roof Tank (IFRT). The wiper seal is fastened with clamp bars to the rim or riser and “wipes” up and down the tank shell along with the movements of the internal floating roof, this seals of the rim gap. The Polyethylene foam which is used for the wiper seal, has a “cross-linked” and closed cell structure. This means that de linear polymer structure has changed into a three-dimensional structure. This makes this material extremely chemical resistant.

If this information has triggered your interest, please click HERE to receive a quotation.

Each seal we supply will be customized to fit to the tank to ensure optimal performance without gaps. We also ensure long services life and safe operation. Internal floating roof primary seals include a variety of configurations, component sizes and material options to handle any application and stored product.

Solutions:

- Single wiper seal (economic choice)

- Double wiper seal (economic choice)

- Liquid mounted mechanical shoe plate sea

- Foam seal

COMPRESSION SHOE SEAL

If you are looking for a versatile seal with an inexpensive construction, this is the seal of choice. One of the innovations introduced by our management over the years is the compression shoe plate seal. This seal type combines the simple and low maintenances characteristics of the traditional compression plate seal with the excellent sealing efficiency of the shoe plate seal. Thie ENVISEAL IC has the same construction as the external floating roof model, but is tailored to internal floating roofs.

This seal uses compression plates to generate the sealing pressure against the tank shell, which is strengthened with a stainless steel leaf spring. The vapor barrier made of PTFE, which is located between the stainless steel plates ensures the vapor tightness of the seal.

If this information has triggered your interest, please click HERE to receive a quotation

This basic design will be tailored to each specific tank. This combination of proven technology and consideration for specific tank geometry makes our ENVISEAL sealing systems the best available technology for emission reduction on internal floating roof tanks.

The Enviseal IC is also available in PVDF, which combines uniform product compatibility with lowest possible weight and long durability.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Optimal service life (expected more than 30 years)

- Best available emission control technology per epa and ippc bref

- Optimal operability in all hydrocarbons and chemicals, including 100% aromatics

- Custom designed and manufactured for each specific tank and product service