EFR Primary Seals

The Primary Emission Barrier

Over the years our mechanical shoe plate seal has proven to be one of the most resilient and versatile solutions for sealing the gap between the tank shell and floating roof. It combines excellent sealing characteristics with very good product compatibility.

The ENV 1 tank seal consists of metal shoe plates that connect to the tank shell, these shoe plates are supported by with scissors and pushed against the shell with special leaf springs. The durable vapour barrier completes the seal.

If this information has triggered your interest, please click HERE to receive a quotation

Solutions

SHORT INSTALLATION TIME WITH EXPERIENCED SUPERVISOR OR FULL CREWS

DURABLE WITH LOW TOTAL COST OF OWNERSHIP

TURN KEY SOLUTION. ENGINEERING, SUPPLY AND INSTALLATION AVAILABLE

SUITABLE FOR BOTH WELDED AND RIVETED TANK SHELLS

COMPRESSION SHOE SEAL

If you are looking for a versatile seal with an inexpensive construction, this is the seal of choice. One of the innovations introduced by our management over the years is the compression shoe plate seal. This seal type combines the simple and low maintenances characteristics of the traditional compression plate seal with the excellent sealing efficiency of the shoe plate seal.

This seal uses compression plates to generate the sealing pressure against the tank shell, which is strengthened with a stainless steel leaf spring. The vapor barrier made of PTFE, which is located between the stainless steel plates ensures the vapor tightness of the seal.

This basic design will be tailored to each specific tank. This combination of proven technology and consideration for specific tank geometry makes our ENVISEAL sealing systems the best available technology for emission reduction on external floating roof tanks.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Optimal service life (expected more than 30 years)

- Best available emission control technology per epa and ippc bref

- Optimal operability in all hydrocarbons and chemicals, including 100% aromatics

- Custom designed and manufactured for each specific tank and product service

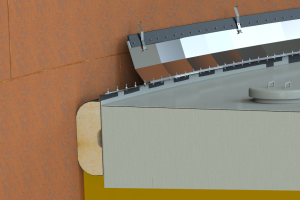

SCISSOR SHOE PLATE SEAL

Over the years our mechanical shoe plate seal has proven to be one of the most resilient and versatile solutions for sealing the gap between the tank shell and floating roof. It combines excellent sealing characteristics with very good product compatibility. The ENVISEAL S tank seal consists of metal shoe plates that connect to the tank shell, these shoe plates are fitted with scissors and pushed against the shell with special leaf springs. A suitable vapour barrier completes the seal.

This basic design will be tailored to each specific tank. This combination of proven technology and consideration for specific tank geometry makes our ENVISEAL sealing system the best available technology for emission reduction on external floating roof tanks.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Optimal service life (expected more than 30 years)

- Best available emission control technology per epa and ippc bref

- Optimal operability in all hydrocarbons and chemicals, including 100% aromatics

- Custom designed and manufactured for each specific tank and product service

ENVISEAL SP PANTOGRAPH SEAL

The Pantograph Primary Seal one of the most widely used seal on Floating Roof Tanks and has been used on large tanks storing virtually all Crude and Refined products. This tank Seal is designed with flexures built into the sheets to ensure conformity with the tank shell and allow expansion and contraction.

The weighted pantograph system ensures that the sealing ring is held in constant contact with the tank shell. The sealing ring extends into the product to ensure vapor retention and above the rim to ensure rainwater drains on to the Pontoon with the space between the sealing ring and the roof is closed by a vapor-tight flexible continuous seal material. Shunts are used at intervals of 3 meters or less to maintain electrical continuity between the roof and the tank shell over the whole range of possible rim gaps.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Optimal service life (expected more than 30 years)

- Best available emission control technology per epa and ippc bref

- Optimal operability in all hydrocarbons and chemicals, including 100% aromatics

- Seals can be supplied per api rp 545

OPTIMUM EMISSION REDUCTION FOR LOW TURNOVER TANKS

The foam seal is one of the most effective primary tank seals when considering emission reduction. With this sealing system the resilient foam core provides a uniform sealing force regardless of the shape of the tank shell. A hold down plate and reinforced polymer fabric provide maximum sealing pressure against the tank shell. This seal has a large contact area and is therefore a very tight seal. Primary foam seals can either be vapour mounted or liquid mounted.

The liquid mounted foam seal completely avoids vapour formation, but the direct contact between the liquid and the seal envelope however makes the requirements for the envelope material much more demanding. When executed in vapour mounted variation the foam seal is not in direct contact with the product, which reduces the requirements for the envelope.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Good operability in all hydrocarbons and chemicals up to 25% aromatics

- Available as vapour mounted or liquid mounted seal design

- Custom designed and manufactured for each specific tank and product service

- Best available emission control technology per epa and ippc bref

- Compliant with all major international (environmental) standards

SCISSOR SHOE PLATE SEAL WITH WAX SCRAPER

Over the years our mechanical shoe plate seal has proven to be one of the most resilient and versatile solutions for sealing the gap between the tank shell and floating roof. It combines excellent sealing characteristics with very good product compatibility. The ENVISEAL SW tank seal consists of metal shoe plates that connect to the tank shell, these shoe plates are fitted with scissors and pushed against the shell with special leaf springs. A suitable vapour barrier completes the seal. This seal is equipped with overlapping wax scrapers, that reduce buildup of product residues on the tank shell

This basic design will be tailored to each specific tank. This combination of proven technology and consideration for specific tank geometry makes our ENV1 sealing system the best available technology for emission reduction on external floating roof tanks.

Solutions:

- Liquid mounted gas tight seal type for maximum emission reduction

- Reduces wax buildup on shells of crude tanksBest available emission control technology per epa and ippc bref

- Optimal operability in all hydrocarbons and chemicals, including 100% aromatics

- Custom designed and manufactured for each specific tank and product service