envideck nc

The current range of IFR is the result of more than 20 years of experience in design, installation and maintenance of IFR. Few other designers can claim this extensive experience.

Òur series of internal floating roofs were developed to meet the demand for durable, high quality internal floating roofs that are economic in investment and optimal in emission reduction. In every step of the design process we have taken into consideration constructability, maintainability, cost effectiveness and care for the environment. This has resulted in an unrivalled innovative new range of IFR.

All roofs are suited for any type of rim-seal, where buoyancy is optimized per seal type.

The NC Aluminum Internal Floating Roof is a cost-effective, proven IFR technology that has been protecting stored liquid products in aboveground storage

tanks for over many years. Constructed of corrosion-resistant aluminum alloys, the interconnecting grid structure provides a high strength-to weight ratio that easily handles loads generated by product turbulence and inspection personnel. This IFR is fully compliant with API Standard 650-H.

Sustainability

Our aluminum floating roofs are designed for reducing environmental impact of the industry. Completely in line with this purpose we aim to take the same care for the environment in our whole production process. From design to production and installation we aim to reduce the impact of our products. We use 100% circular aluminum materials for our structural components, produced by the world’s cleanest and most energy-efficient aluminum production technology. We reduce machining times through smarter designs and limit the exposure to a possible hazardous atmosphere during installation. This results in optimal solutions with minimal negative impact

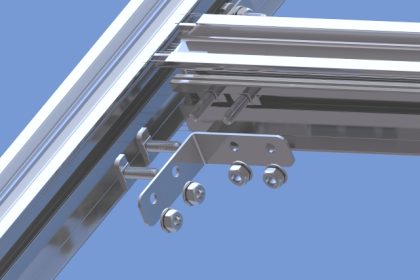

Envideck®roofs are designed with extruded continuous threaded bolting channels. These channels prevent vapors from escaping through the bolt holes and provide more strength to the connection when compared to any other design in the market.

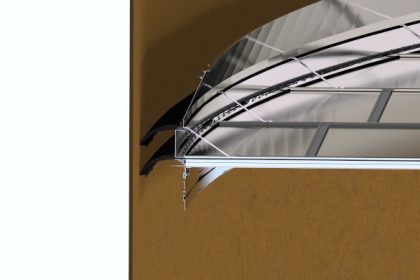

• Our unique rim extrusion allows for installation of any seal without the need for making holes in the rim.

• The leg supports connect to the girder structure instead of between the pontoons allowing for repeated

flexing without structural failure. Girder spacing does not exceed 1,5m .

• Extruded 10 inch pontoons are attached to the roof without using pontoon saddles and straps.

• Pontoons are not structural components, they do not contain gussets and are not interconnected. The maximum spacing between pontoon rows is 3m

•Standard deck sheeting is AL 5052 0.025”nominal thickness which is 25% heavier than the minimum allowed by standards.

• The heavy rim of the IFR is extruded and rolled to diameter. The connection to the roof and the seal can

be made without penetrating bolts, this creates a no-emission roof